Machining Centers

GS-SERIES

The ALZMETALL GS series was designed to combine rigidity and damping properties. The thermo-symmetrical structure of the entire base frame – right down to the spindle – always reliably controls the force transmission during the machining process. The advantages are maximum accuracy and machining precision on the workpiece as well as maximum cutting performance – even in heavy-duty cutting.

- Solid, rigid base frame made of grey cast iron

- Dynamic stressed machine coponents are made of nodular cast iron

- ALZMETALL-specific gantry concept (ASGK) with box-in-box system

- Fourfold linear guide system in the Z slide (Z axis)

- Rotation axes (A and C axis) with torque drives, optional

- Hybrid machining (miling, turning, grinding) in one wordpiece setup

BENEFIT FOR USER

Closed power flow between workpiece and tool as well as geometrically symmetrical structure of the X-Y-Z coordinate carriage

-

GRANTS

- Thermal stability at Tool Center Point (TCP) in X-Y-plane without compnsation

- Reduction of tool costs

- OPTIMIZES

- Contour accuracy at high path speeds

- Lifetime of main spindle

- GUARANTEES

- Extremely high parallel traversing accuracy due to double drives in the X and Y axes

- Significantly lower Total Cost of Ownership (TCO) over the lifetime of the machine

Find the right machining center for your project

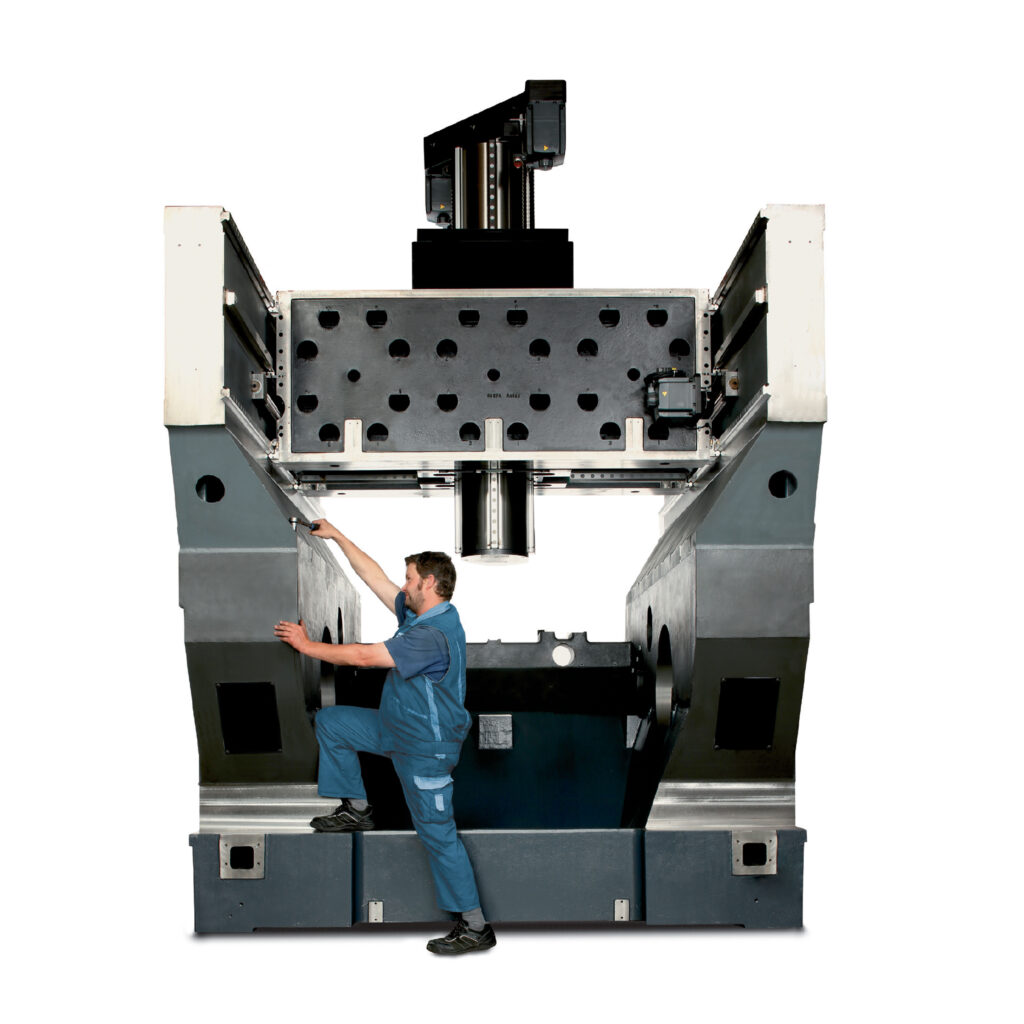

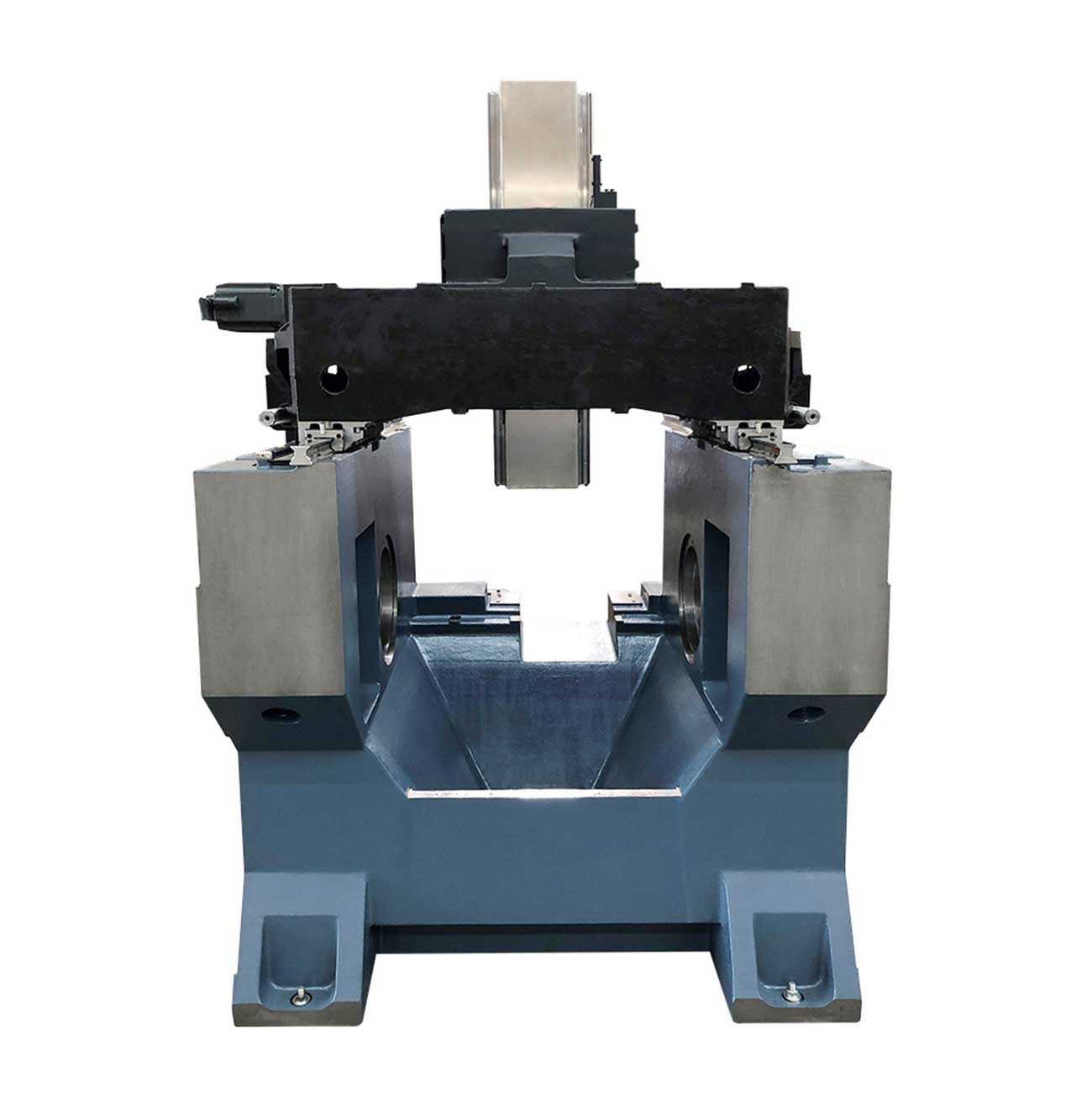

BASE FRAME

Using a GS 1400 as an example

The “Heavy Weight” for Milling and turning

Extremely rigid, integral base frame made of one piece

All statically stressed frame components are made of grey cast iron

All dynamically stressed machine components are made of nodular cast iron

Picture: Basic structure of the GS 1400

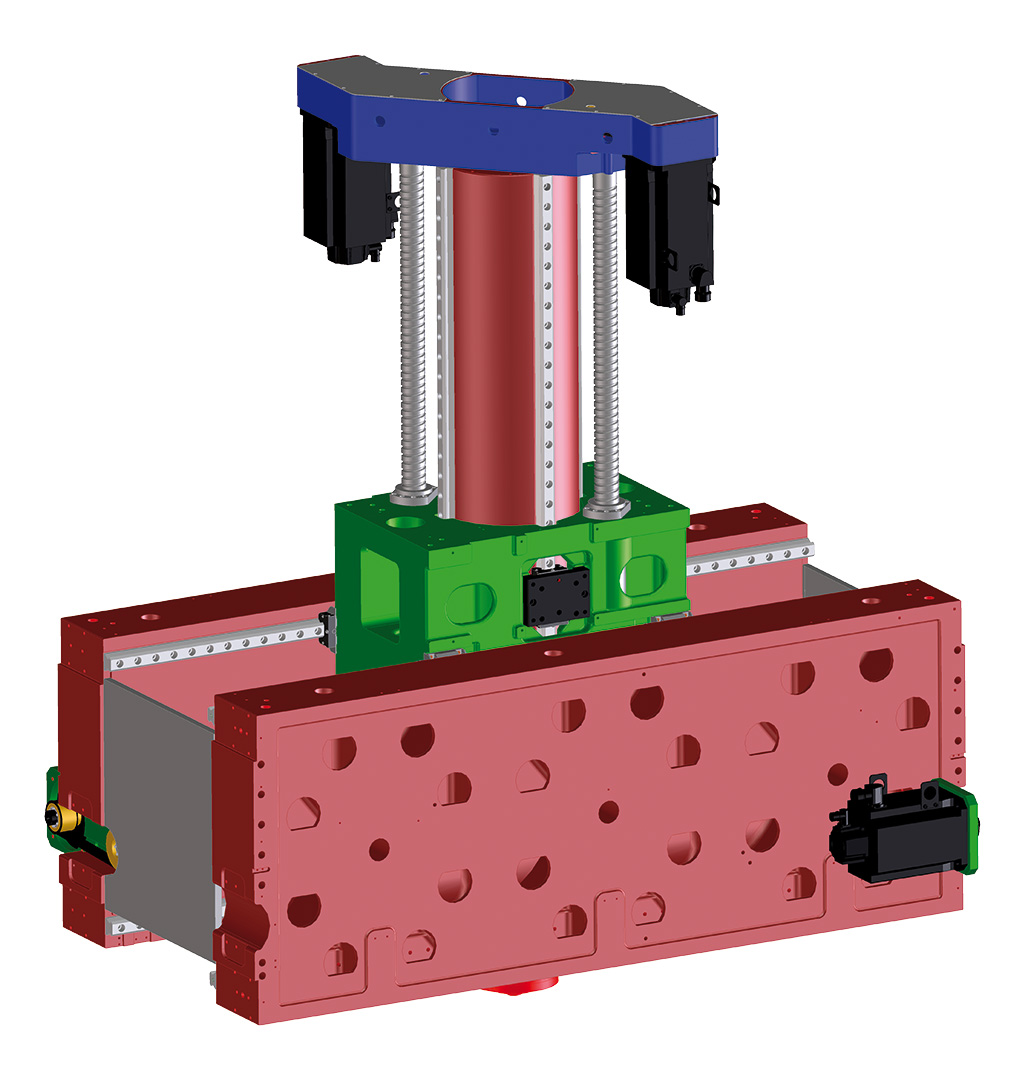

Picture: travel system carriage of the GS 1400

TRAVEL SYSTEM CARRIAGE

Design Caracteristics

Carriage designed as a Box-in-Box system with symmetrical structure and restrained mono block cross slide as well as integrated Z-axis slide and motor spindle.

Multiple guide-ways in all linear axes.

Single and double ball screws with Servo drives of the linear axes.

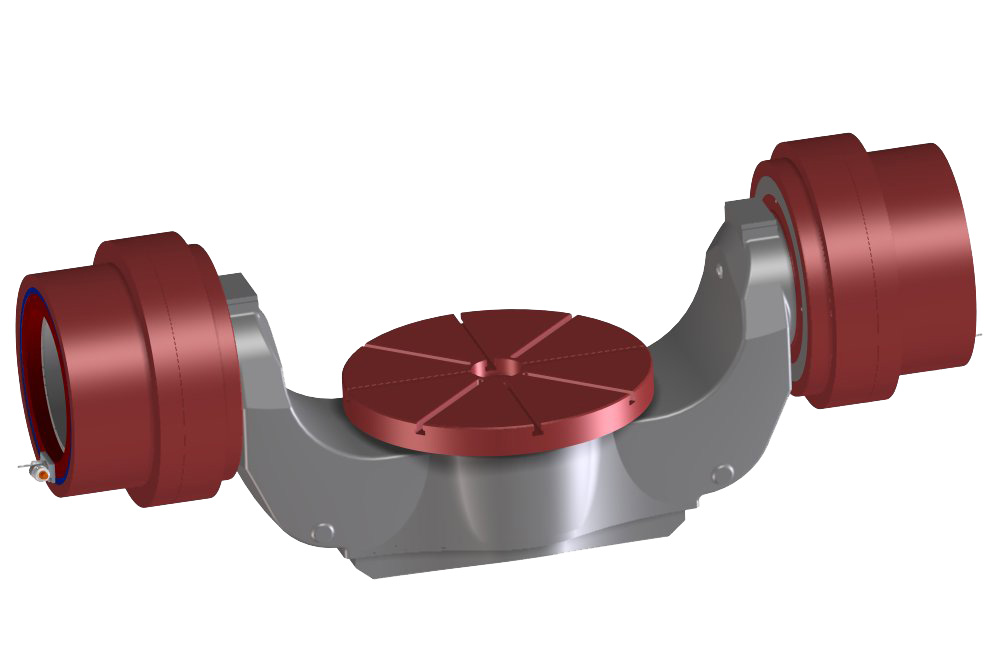

NC SWIVEL AND ROTARY TABLE (SDK)

Gear or torque drive technology according to application-specific design.

Gear drive in swivel and rotary axes for economical 5-axes machining.

Torque motors are direct, rotary drives for highly dynamic, oscillating machining tasks.

Picture: NC Swivel and rotary table (SDK) of the GS 800NE

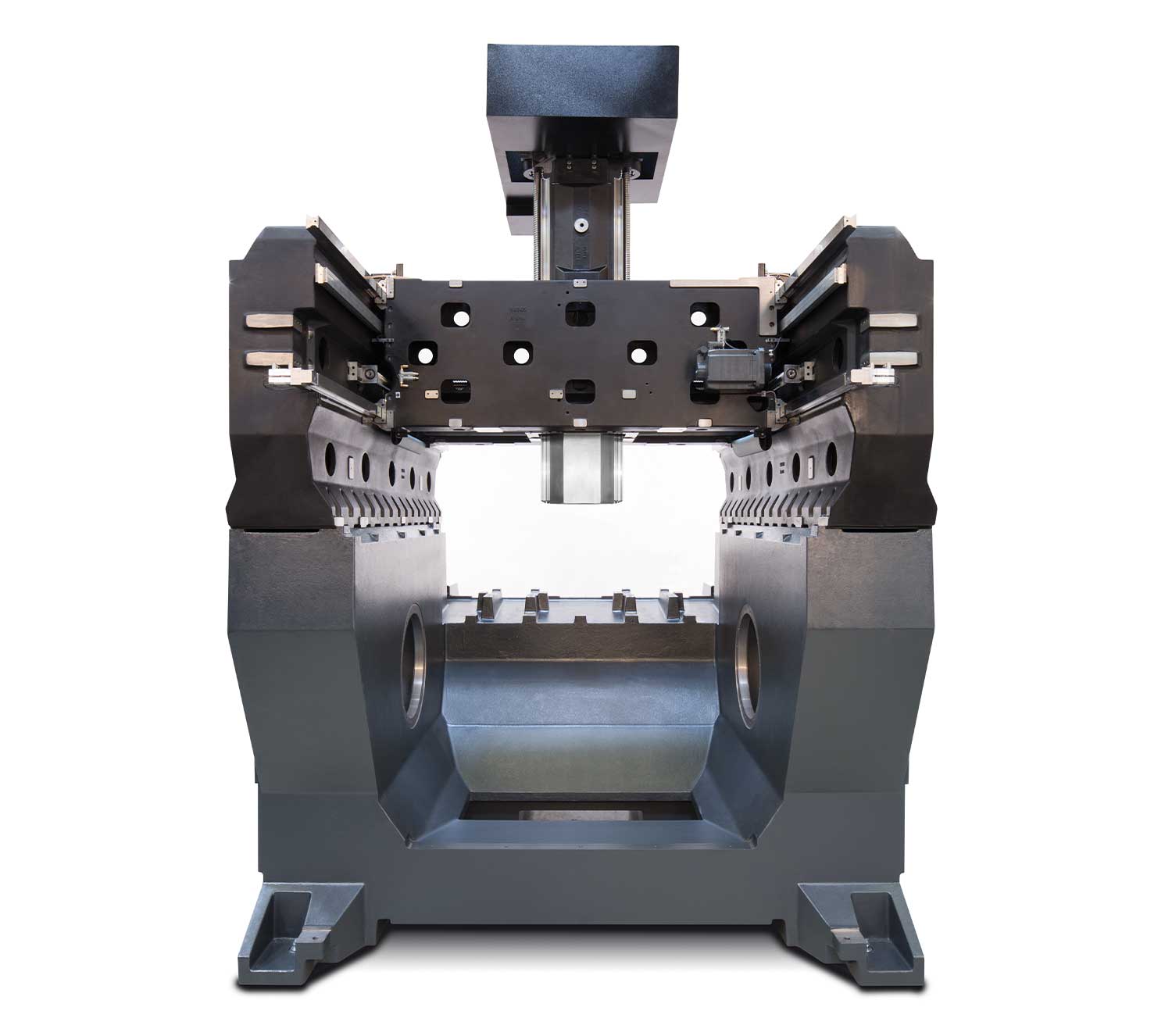

Picture: ALZMETALL-SPECIFIC GANTRY-KONZEPT (ASGK) of the GS 1200

GANTRY-CONCEPT

ALZMETALL–SPECIFIC GANTRY-KONZEPT (ASGK)

– patented –

The Gantry design:

In the gantry design, the three linear motion axes are assigned to the machine gantry. If the machine has fixed uprights with a movable crossbeam at the top, it is referred to as a bridge gantry design.

GANTRY-CONSTRUCTIONS

Conventional and modified Gantry designs

IN COMPARISON:

- 4-fold internal linear guides

- Deviation(deflection) reduced by a factor of 2.3 and thus

- Rigidity is 2.3 times higher than “on top mounted” systems

- Less positional deviation at the tool center point (TCP) at the same level of acceleration

- Significantly increased cutting tool lifetime

Picture: ALZMETALL-SPECIFIC GANTRY-KONZEPT (ASGK) of the GS 600

AUTOMATION

Automation Solutions tailer-made for economical benefit and full flexibility

Automation is key to success for a highly producitve manufacturing system. It delivers reduced downtime, improves quality and ergonomic working environment. In future it also may help to lower the risk of shortage of skilled workers.

ALZMETALL Automation Solutions are based on standardized modules with interfaces to proven hard- and software components. Customer may choose to buy the interface for automation upfront and purchase automation later.

Automation Erowa EMO

Automation GS 800

SYSTEMS

Production Lines for future manufacturing to combine multible manufacturing processes

Well thought systems combining machining centers with automatic loading and unloading by fixture changes to reduce multiple setups and increase quality.

From planning phase to intelligent automation solutions at first hand.

PRE-OWNED MACHINES

Pre-Owned Machines for the fastest delivery and

self evident at ALZMETALL quality standards

Well thought systems combining machining centers with automatic loading and unloading by fixture changes to reduce multiple setups and increase quality.

From planning phase to intelligent automation solutions at first hand.

Get connected

We will be happy to help and check availability. In case of lacking inventory don’t hesitate to challange our team, we screen our network for you.

Contact

Tel.: +1 980-236-8970

Email: b.epps@alzmetall-usa.com

Birgit Epps